Knowledge base

Expertise from A to H20

What are you looking for?

Membrane filtration

What is LOG reduction?

Microplastics

What are microplastics?

Microplastics

How does microplastic get into water?

Microplastics

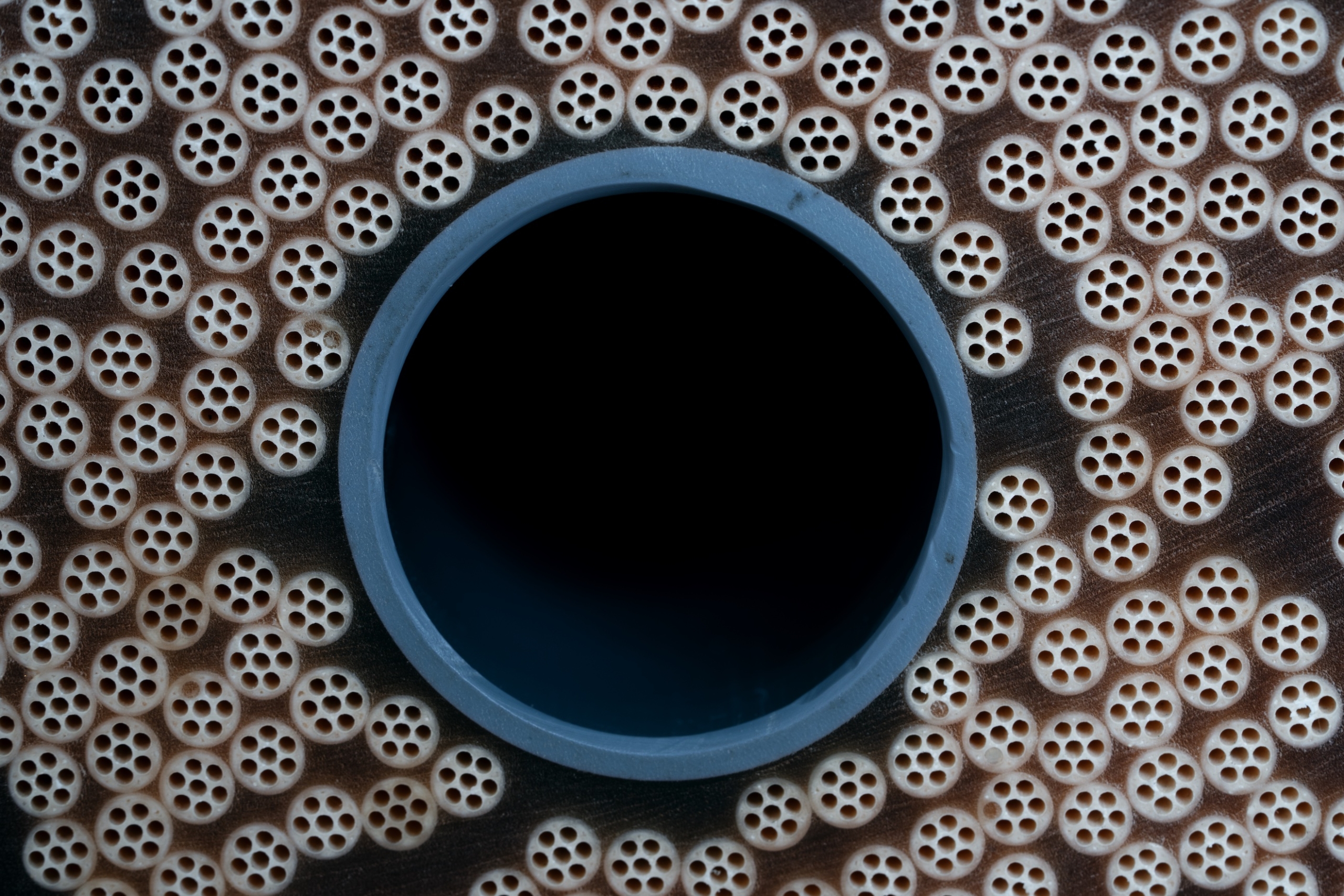

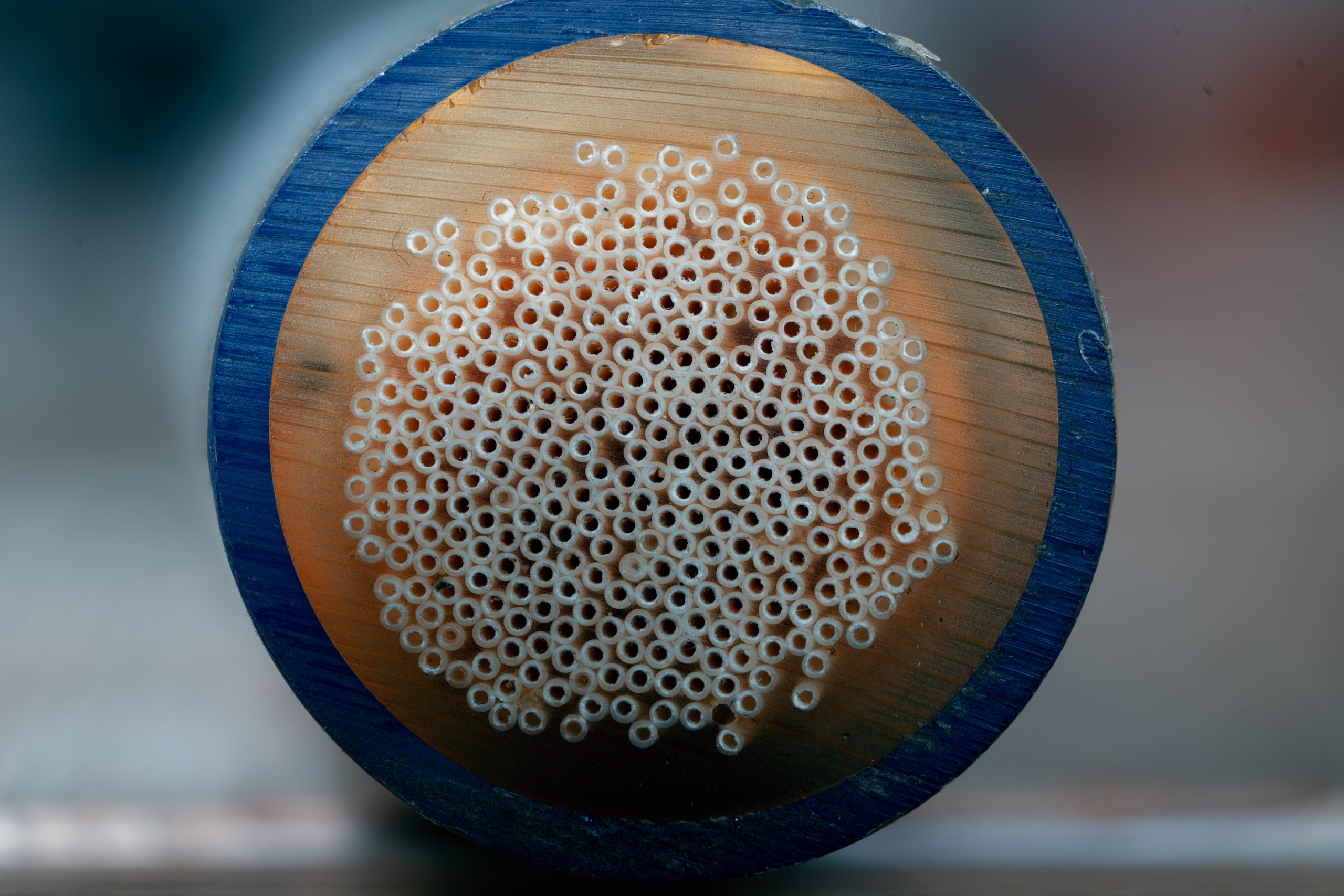

How does a microplastic filter work?

Membrane filtration

What is ultrafiltration?

Membrane filtration

What is nanofiltration?

Membrane filtration